OptimalSlope was contracted by the Think & Act Differently mining

business incubator to redesign the starter pit of one open pit mines owned by BHP

in Australia following its successful bid to the call for innovations in “Slope

Engineering”: Unearthed

| Think & Act Differently | Open House Slope Engineering | Overview.

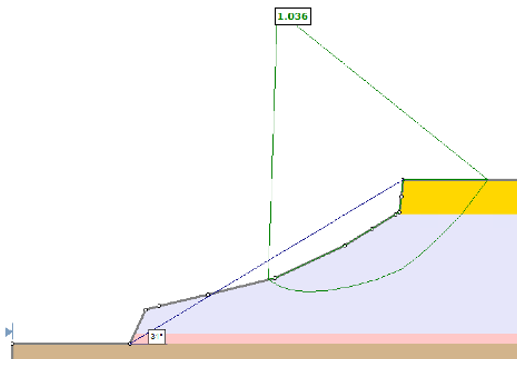

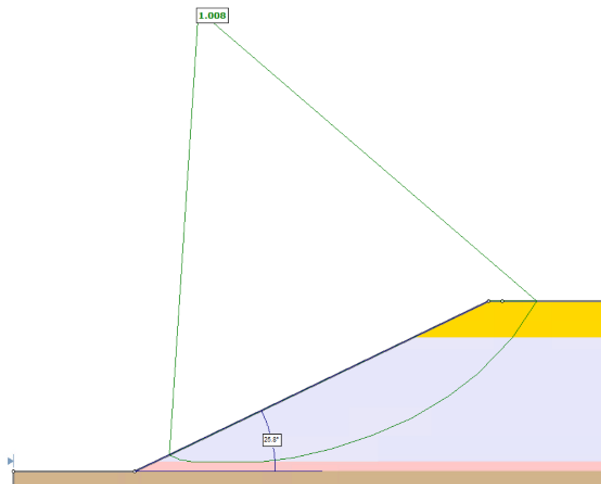

OptimalSlope’s Slope Optimiser produced

geotechnically optimal pitwall profiles achieving significant improvements in

overall slope angles, typically ranging from 3 to 4 degrees, of the thick

overburden to be excavated to gain access to the metalliferous resources (see

Figure below).

An

independent evaluation carried out by BHP mine managers assessed that the optimised

profiles for the overburden were worth of 50 million AUD saving on waste rock

excavation costs.

We are

unable to disclose the mine name due to confidentiality.

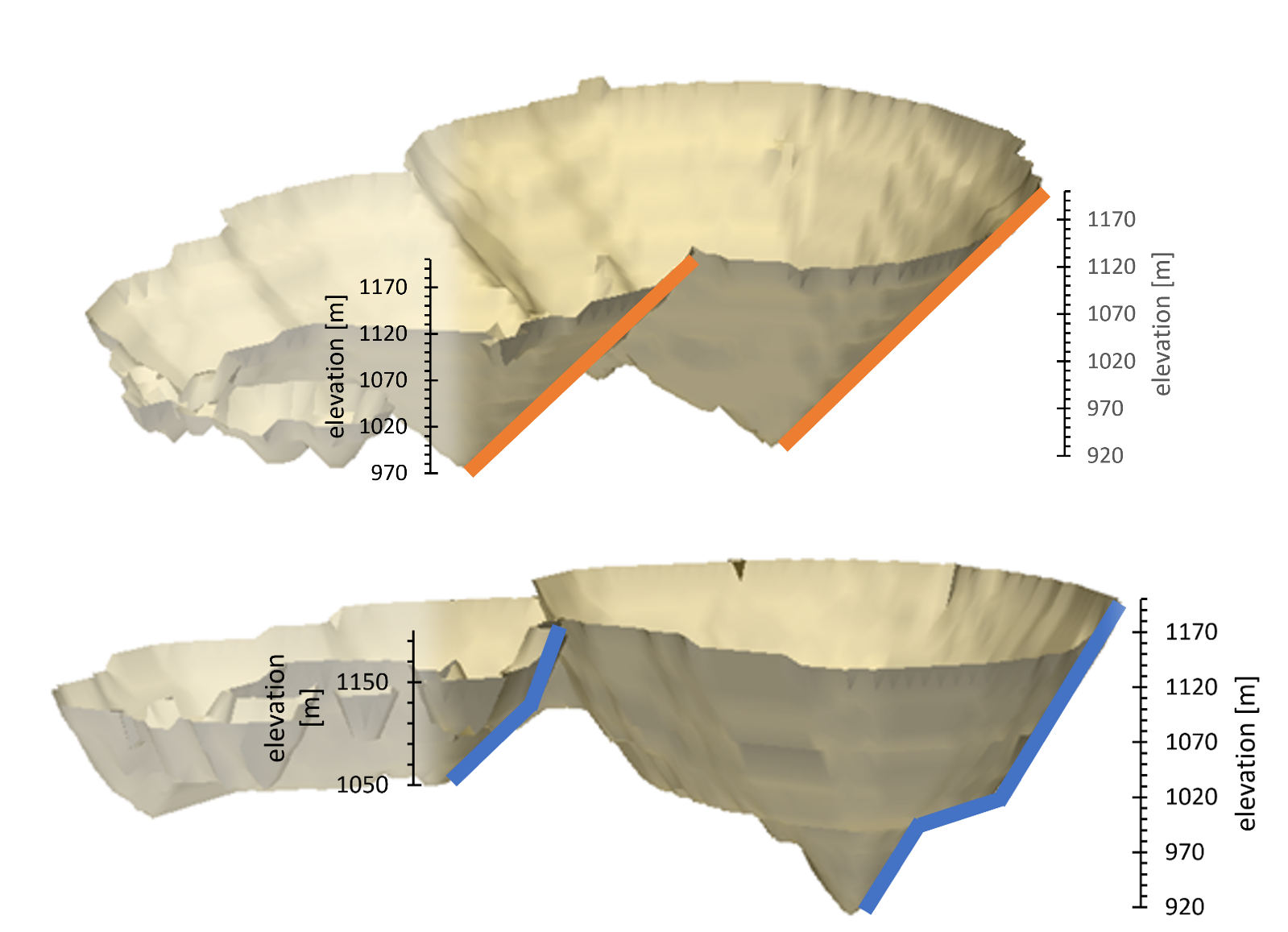

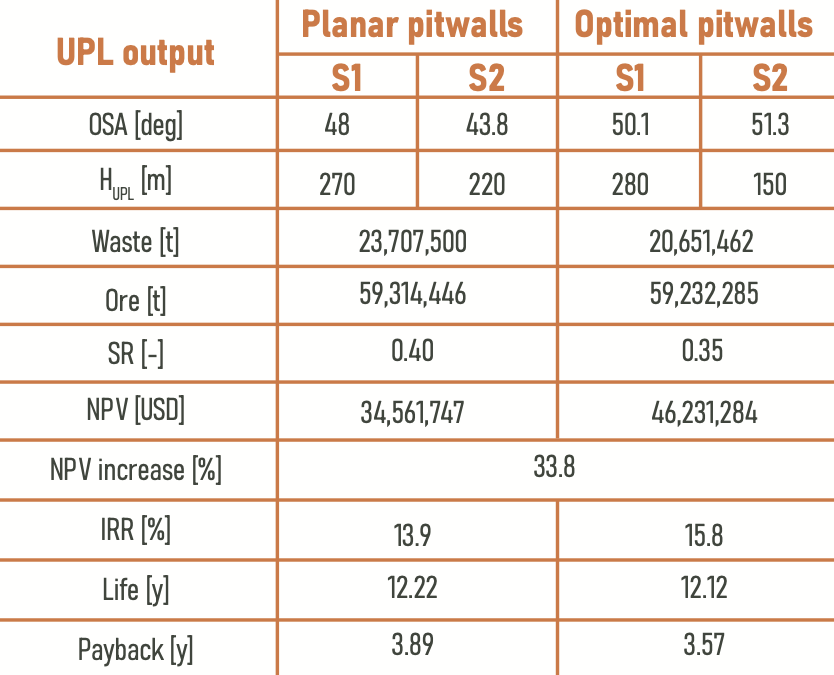

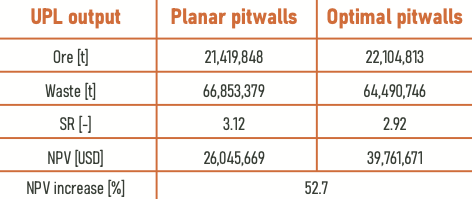

The work on this case study is published in the SME Journal of Mining, Metallurgy & Exploration. The block model, geotechnical and economic data were provided by AMTC (University of Santiago, Chile). To showcase the gains achievable by OptimalSlope, two independent designs were carried out using Geovia Whittle: first employing planar pitwalls as per traditional methodology, and secondly adopting the optimal pitwall profiles from OptimalSlope. The results are summarised in the table below. A representative 2D cross-section was assumed for the design of the pitwall in each mine sector. The Factor of Safety (FoS) of the profiles calculated by OptimalSlope was verified by stability analyses performed by Rocscience Slide 2 and FLAC3D.

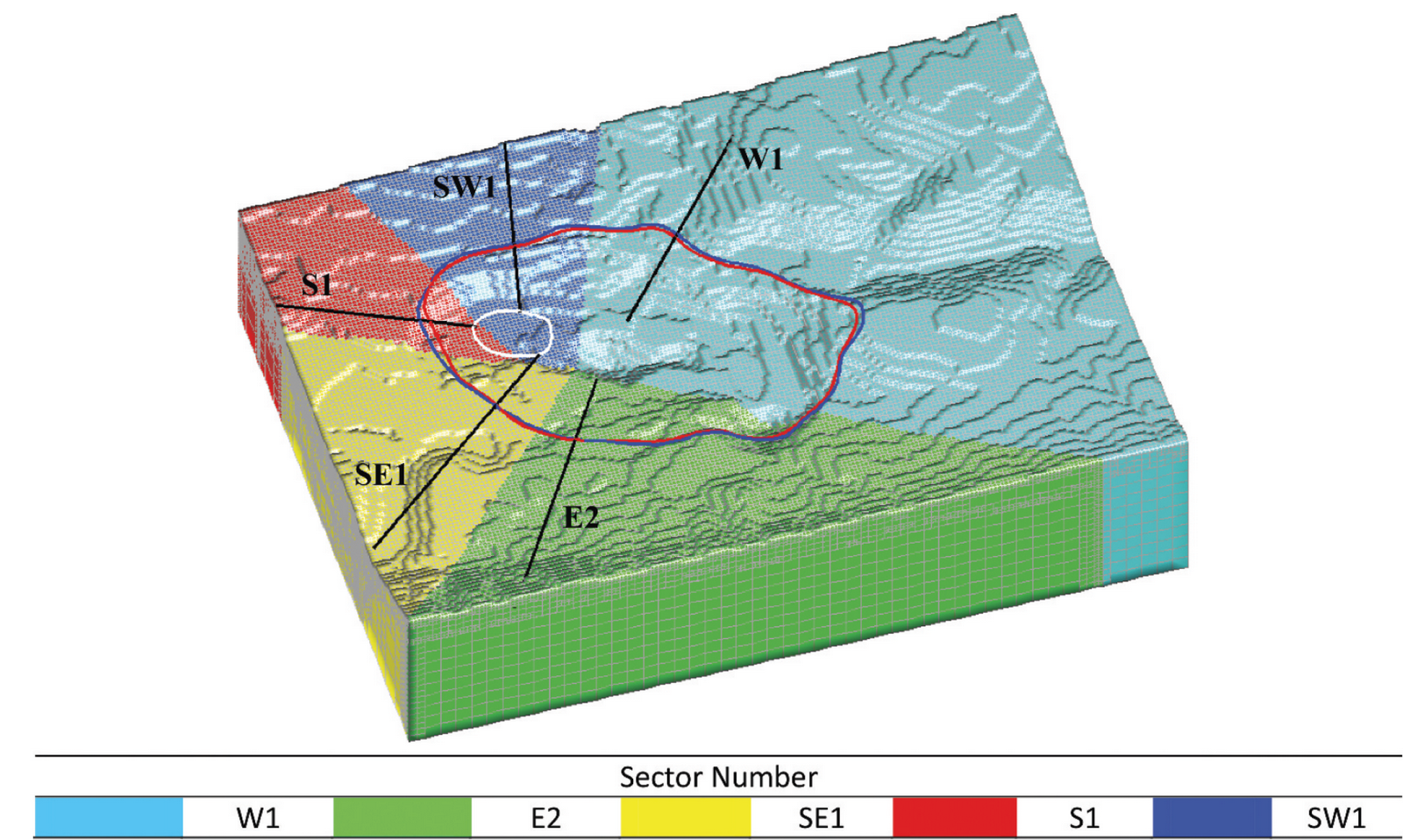

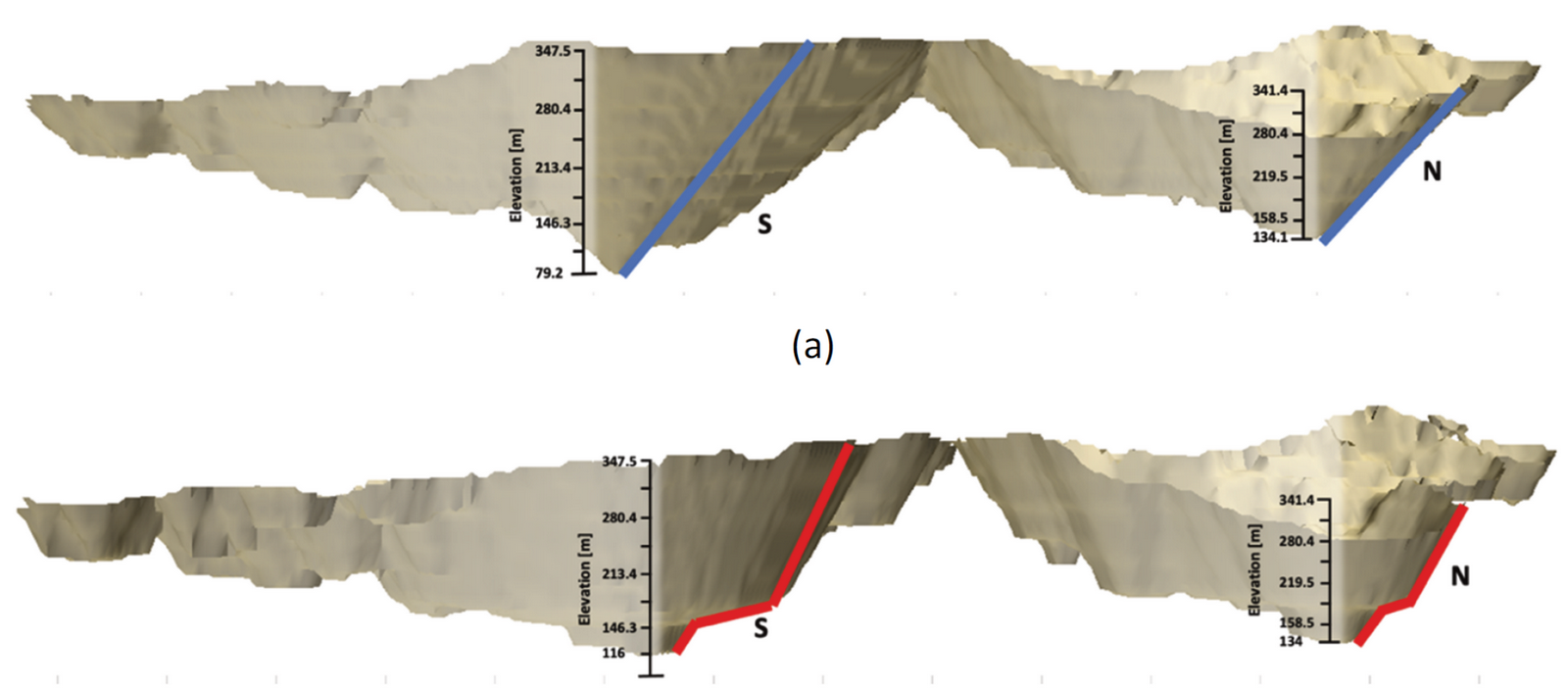

The work on this case study is published in the CIM Journal. The block model, geotechnical and economic data for the mine were provided by Kinross. To showcase the gains achievable by OptimalSlope, two independent designs were carried out (one for the traditional pitwalls and one for optimal pitwalls) using Datamine. Due to the complex geology the pit was divided into five geotechnical sectors, each requiring a different pitwall profile. The results are summarised in the table below. The Factor of Safety of the profiles calculated by OptimalSlope was verified by stability analyses performed by Rocscience Slide 2 and FLAC3D.

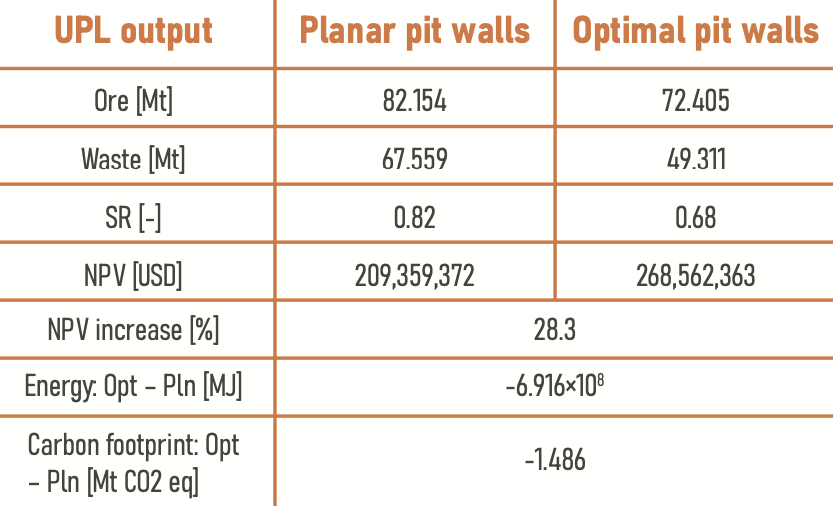

The work is published Open Access in the proceedings of the International Slope stability in Mining Conference 2021 in Perth. The block model and economic data for the mine were taken from MineLib, a publically available repository of open pit mine data. This means that the design and calculations reported in the paper can be replicated by anyone. The two independent designs were carried out using Geovia Whittle. The results are summarised in the table below. The Factor of Safety of the profiles calculated by OptimalSlope was verified by stability analyses performed by Rocscience Slide 2 and FLAC3D.

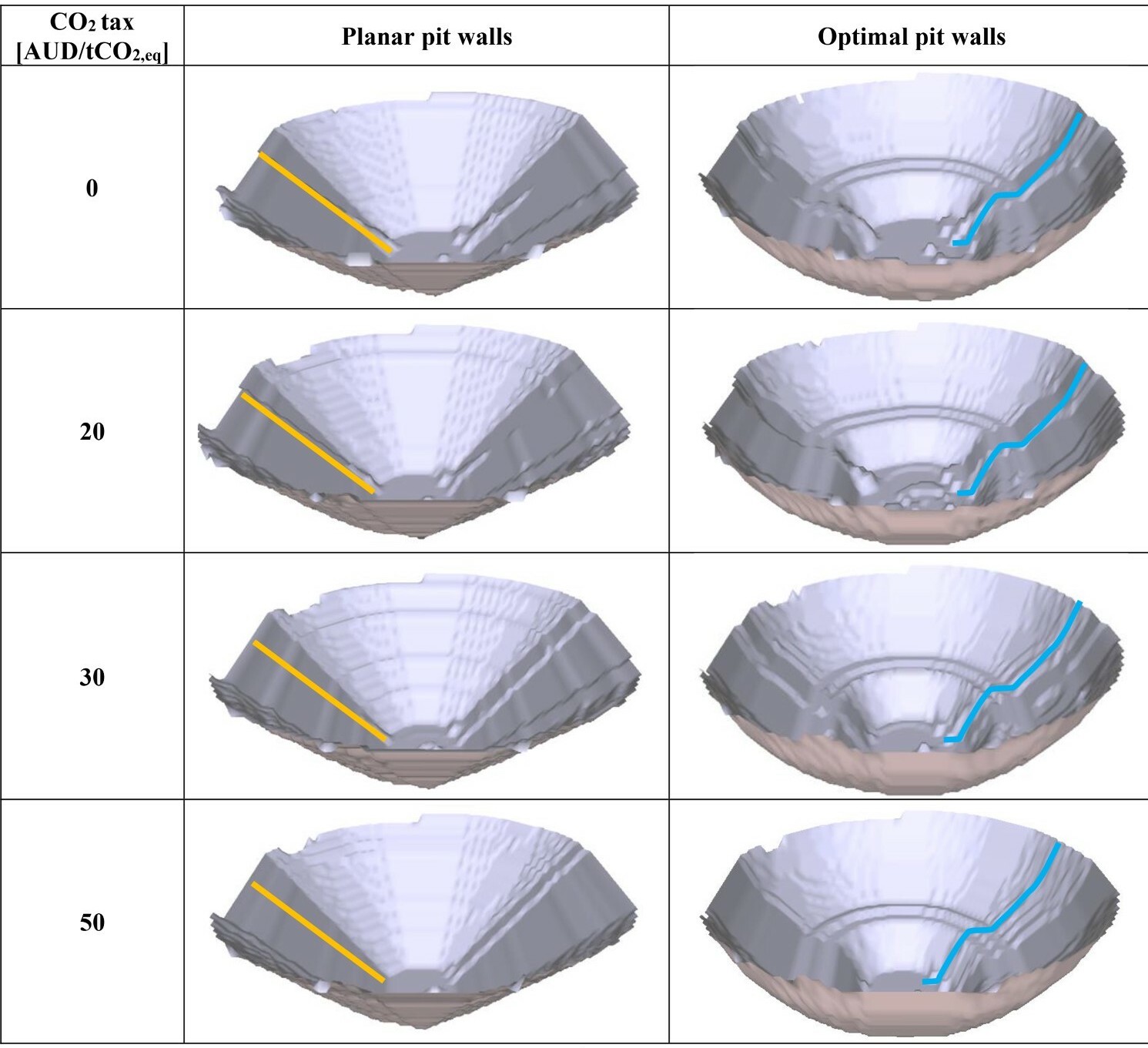

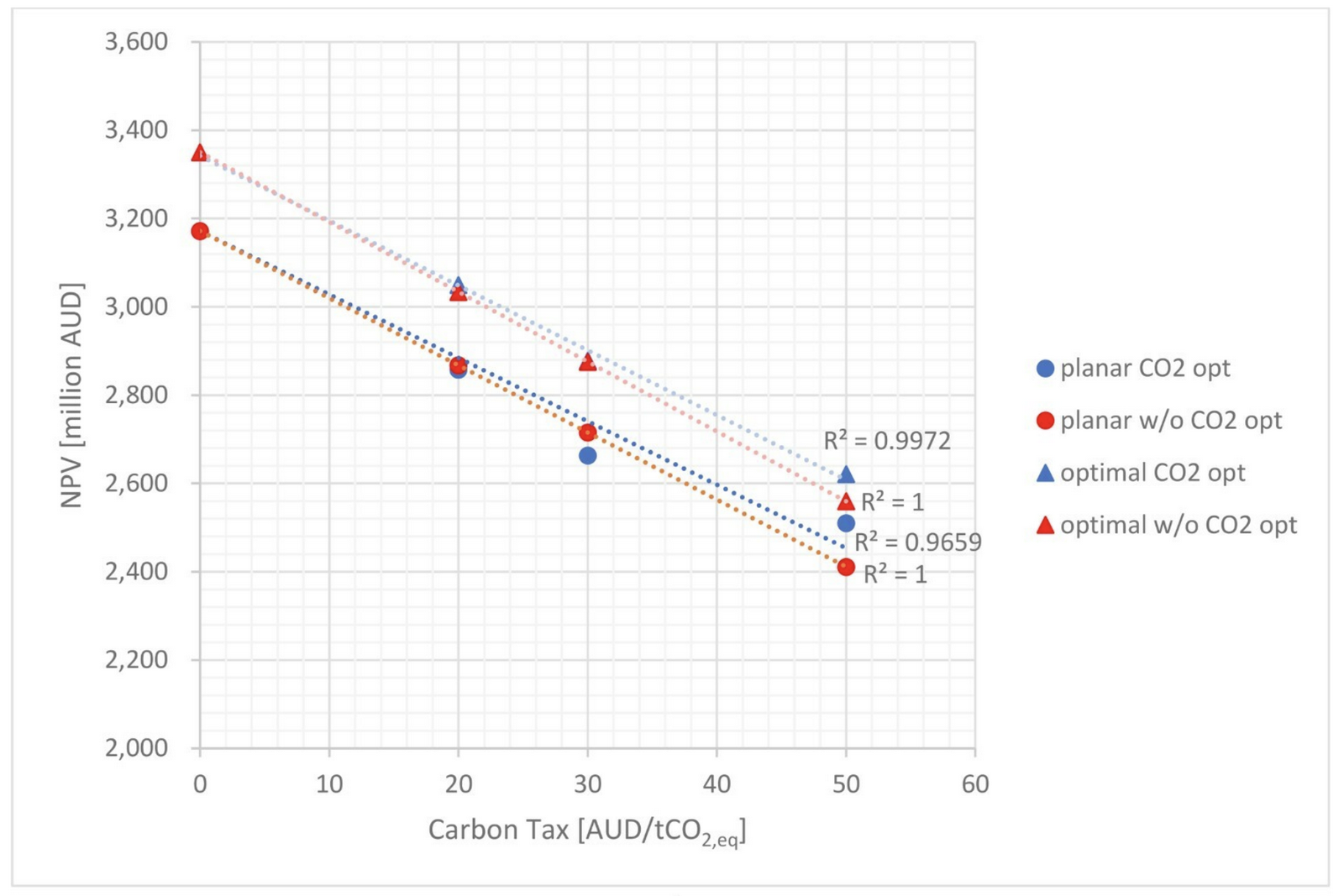

The work on this case study is published in Mining Technology. This paper investigates the financial and environmental consequences stemming from the introduction of a carbon levy applied to mining and processing activities. The Marvin copper deposit (block model data publicly available from MineLib repository) was adopted as a case study. Several pit optimizations were performed based on four different values of carbon tax and adopting either traditional planar or non-linear optimal pitwalls. It emerges that the relationships between carbon tax value versus NPV, amount of ore extracted, and carbon emissions exhibited linearity in both cases of planar and optimal pitwall profiles. Moreover, the adoption of optimal profiles realizes gains up to 215 million AUD, without compromising the safety of the UPL.

The work on

this case study is published in the

International Journal of Mining, Reclamation and Environment. We worked with the international

geotechnical mining consultancy Call & Nicholas which provided the geotechnical data for the

case study.

The mine

considered here is located in Mexico into Cretaceous siltstone featuring a

large amount of discontinuities: eight different joint sets and a primary

bedding plane. These fractures together with tension cracks were accounted for

by Slope Optimiser to determine the optimal shape of the pitwalls. To replicate

the effect of joints on slope stability, direction-dependent cohesion and

internal friction angle parameters were employed. Key inputs include joint

orientation, non-persistence, and probability of occurrence.

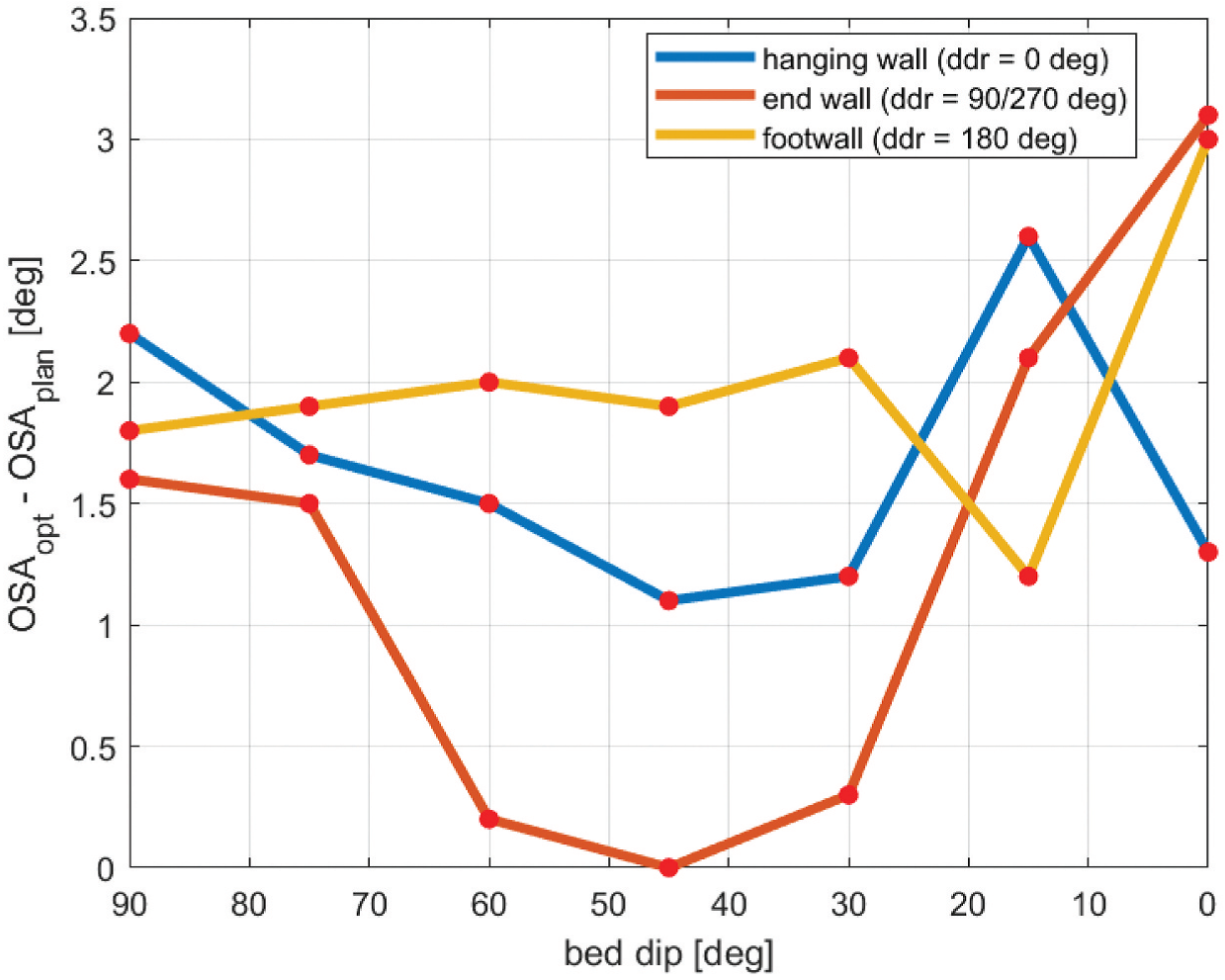

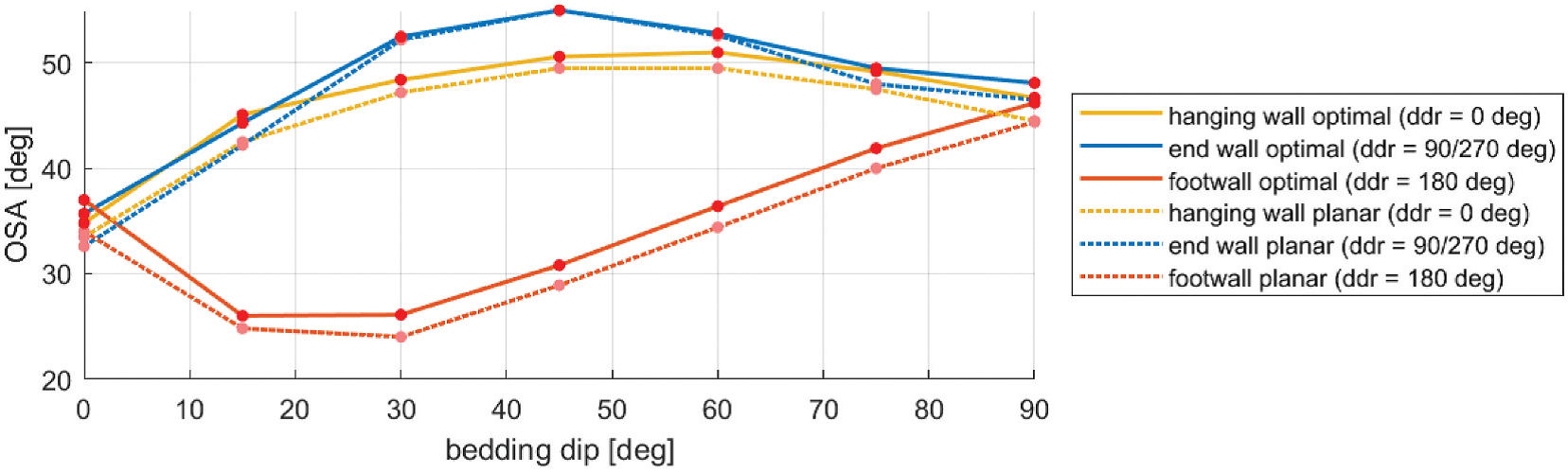

Optimal

pitwall profiles were determined for various combinations of bedding dip angles

(0°, 15°, 30°, 45°, 60°, 75°, 90°) and mine pitwall orientations (hanging wall,

footwall, side walls), considering the three-dimensional kinematics of the

joints through anisotropic functions of cohesion and friction angle. Results

indicate that the optimal pitwall profiles exhibit higher OSA compared to

planar profiles with the same FoS of up to 3 degrees. Additionally, stability

analyses performed using Rocscience Slide2 independently verified the FoS

values of the optimal profiles.